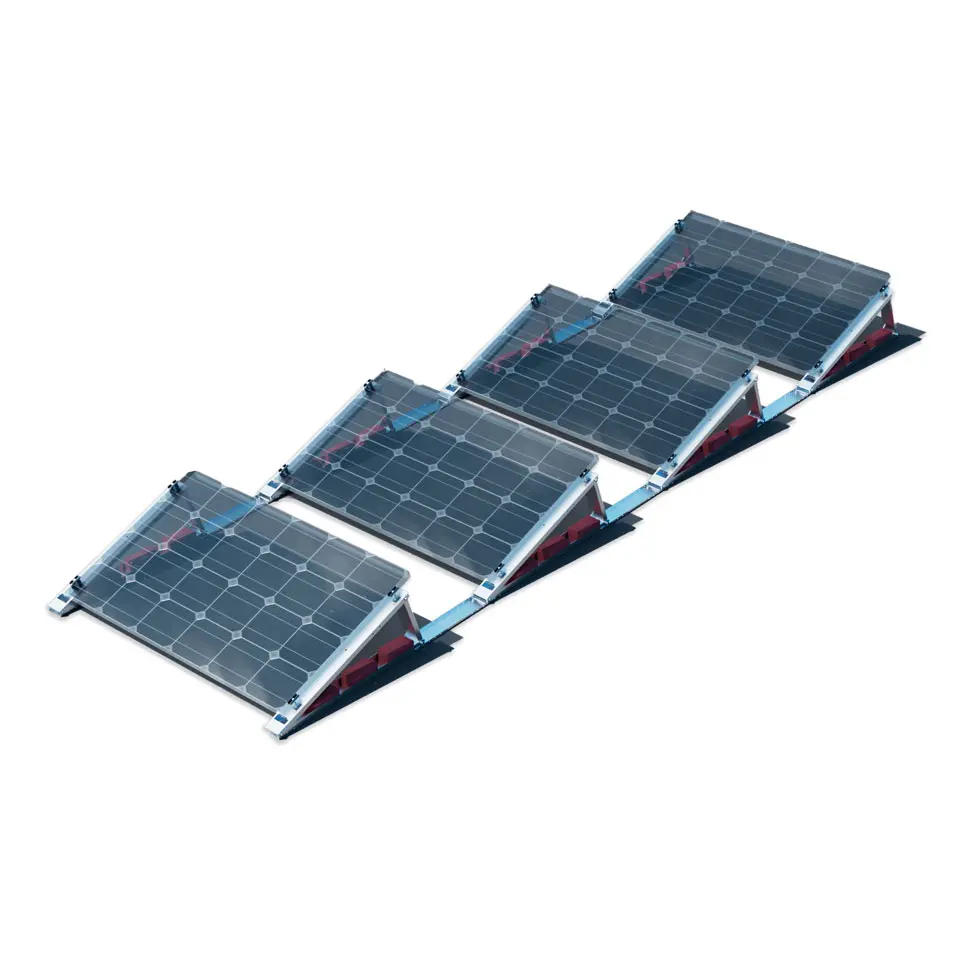

Traditional panel placement for flat surfaces [FLAT-S]

The classic way is to orient panel surfaces heading south [FLAT-S]. You will have a strong energy peak around noon and a relatively small production in the morning and evening. If you choose a relatively high angle of attack you need large spaces between the panels.

There are some aids for calculating the necessary spacing deoending on the angle of attack, see this table.

Alternative way of panel placement for flat surfaces [FLAT-EW]

An alternative way is like this, panel surfaces headig east/west [FLAT-EW]. You will have a more evenly distributed energy production which in many cases matches your daily consumption profile better. Wind forces are smaller and the whole construction can be more light weight. Spave requirement is also smaller so that more panels fit into the same area. The overall energy produced will be slightly less with [FLAT-EW], however. So, if you have a really large battery and a strong concrete floor [FLAT-S] may be a little better. But generally speaking, we have a preference for [FLAT-EW].

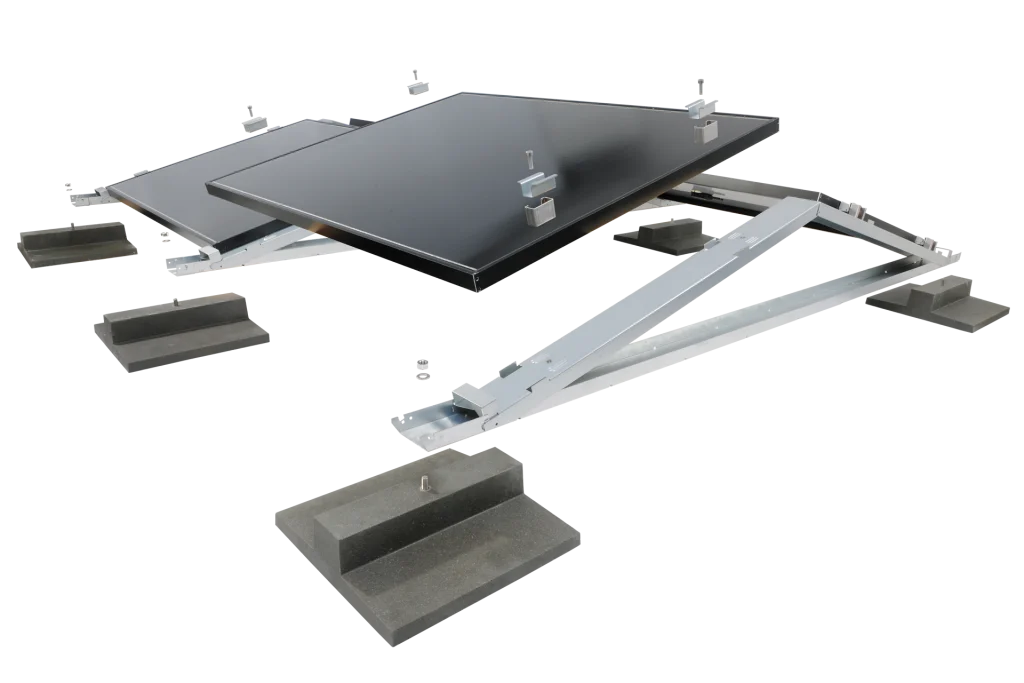

In both cases you must be careful not to violate the roof covering, which will usually be a layer of bituminous roofing felt (tar board). You should place an additional layer of this material under the points where the metal pieces of the stands touch the roof. No screws must be used. Just put some paving blocks at the places which are designed for them.

A combination is possible [FLAT-EW-S]

Although you will not find this constellation frequently it unites the best of two worlds. You would place 80% of your panels EAST/WEST and at the northern side of your area you add one row of panels facing south with a really steep angle (70 degrees or so). They will give high yield in winter when the sun is very low on the horizon. ES-Micro systems support this kind of panel arrangement perfectly because each panel has its own power point tracker. If you plan to have an ES-Hybrid system, however, you should not connect the “winter panels” to one of your two strings because they would create a bottleneck for them in the morning or late afternoon. Instead you should connect these panels to separate micro inverters (ES-Micro). The energy produced by these panels then goes directly into your AC home grid, which means that it cannot be stored in the HV battery of your ES-Hybrid system. But this is not a problem because the main pourpose of these panels is to harvest energy in winter when there is generally less sun light available and you will probably consume the generated energy directly anyway.

Considering weight

The total weight including pavement stones, aluminium rods and panels will be between 12 and 33kg / m² – which is a significant difference. Old panels usually are heavier, and [FLAT-EW] can live with much less ballast weight. Regions wit7h heavy winds need more ballast. Ask an enigneer to check the statics of your building before you decide.

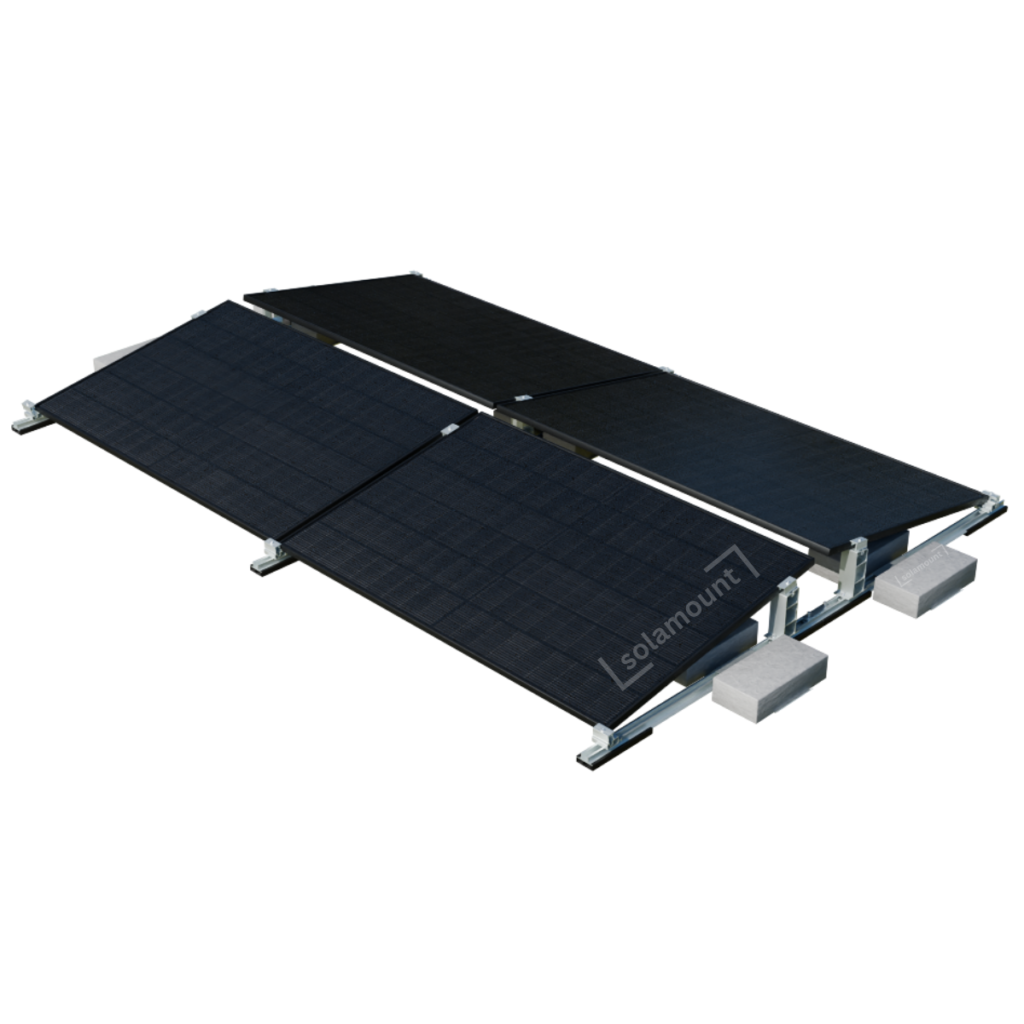

Details on East/ West mounting

It is important to keep some distance between the lower edges of the panels and the roof and also between the top edges of two adjacent edges. This will allow for some air circulation. Hot panels produce less energy than cooler ones.

As you can see the construction shown above has six solid rubber-like pieces which provide places for 12 stones. 2 persons can mount two panels in 10 minutes.

The product shown above is just an example which contains many cleverly designed details. Go and look for similar mounting solutions at your place.

This one is fairly cheap and lead to our estimation of ~40€ / panel.

The ValkBox is another product which you may find interesting.

String Separation and inverter limits

ES-Micro can handle panels with different orientation perfectly. With ES-Hybrid you need to connect all panels facing East to one string and the other ones to the second string. Our ES-Hybrid inverter needs at least 160V in a string for startup. This means that you should have a minimum of 5 or 6 panels in each string. On the other hand you cannot have more than 16 (modern) panels in a string because their idle voltage may go up to 60V and the sum of their idle voltages would become dangerously high (1000V is the tolerable maximum for the inverter).

If you want to have 32 panels facing the same direction you would have to split them into two groups of 16.

The combined placement [FLAT-ESW] would in fact require three strings. As said above you will need a separate string of panels for each direction. The largest ES-Hybrid inverter models (15 kWp) have three power point trackers, the smaller ones only have two of them. Using micro inverters for the south facing panels is a good solution.

Placement on a perfect hip roof

If you have a symmetric hip roof with the same (relatively small) inclination you should really think of putting panels onto each side of your roof. Yes, also on the northern side. These panels will produce 30..40% less energy but panels are so cheap that it is still profitable to use the north facing area. You need four power point trackers for such a roof topology (i.e. two ES-Hybrid inverters). But you would also need the same two inverters if you did not use the northern side of your roof. So the extra cost for integrating the northern area is really only the price for the panels.